|

CO2 Storage: Large-scale Low-cost Demonstration Opportunities in China by Zhong Zheng |

|

| |

|

Figure 1: Showcasing research from the state key laboratory of power systems (Tsinghua University) and the Princeton Environmental Institute (Princeton University) explores Near-Term Mega-Scale CO2 Capture and Storage Demonstration Opportunities in China. (figure from Ref.1) |

|

|

People talk about energy and climate change nowadays; people also talk about greenhouse gas and carbon dioxide. Large amount of CO2 is emitted into the atmosphere, which is considered a main cause of global climate change. So if CO2 is the reason, why don't we prevent it from emitting into the atmosphere? CO2 capture and storage (CCS) is actually a very straightforward idea of doing this, and a number of university and industrial researchers are working on this. CCS: CO2 capture and storageTypically, the CCS technology chain includes CO2 capture from a source, transport to a reservoir, and then injection and storage underground for hundreds of thousands of years. Under a carbon-constrained policy framework, CO2 capture and storage (CCS) is considered an important technology option for fossil-fuel rich countries such as China and U.S.; otherwise the coal industry will not survive the competition due to its high CO2 emission intensity.There are two features for the CCS technology: on one hand, CO2 capture is very expensive, it contributes to as much as 70% of the total cost for a typical CCS project, with CO2 captured from the flue gas of fossil fuel power plants (in which its concentration is 3-15% percent, post-capture projects). The capture cost here is made up of costs for: (i) extraction of CO2 in an appropriate chemical solvent, (ii) the recovery of the CO2 as a pure stream from the solvent and regeneration of the solvent for reuse, and (iii) compression of the CO2 to the pressure needed for transport by pipeline to the CO2 storage site. On the other hand, CO2 storage needs more industrial experience. There are not as many industrial-scale projects on long-period underground CO2 storage. It is now widely recognized that the most significant obstacle to the routine pursuit of CCS is successful demonstration of CO2 storage at “mega-scale” in geological formations such as the deep saline formations. Now we raise a new question, can we just focus on CO2 storage demonstration, without paying the relatively higher cost of CO2 capture? Pure CO2 sources in coal chemical industryIn 2009, I joined a field trip organized by World Resource Institute (WRI) and Tsinghua University to different clean-coal projects in China to collect different stakeholder perspectives. The field trip was partly a joint research project focusing on the guidelines for CCS implementation in China. Participants were mainly university researchers such as Stanford professor Sally Benson and NAE member (National Academy of Engineering, China) Prof Peng Shuping. Others also included industrial experts such as Dr. Xiangkun Ren, then-director of Shenhua Coal-to-liquid Research Institute; and Dr. Song Zheng, then-general manager of the Huaneng GreenGen IGCC project. During the trip, what impressed me most was the observation that almost pure CO2 is supposed to emit into the atmosphere in large amount within the coal chemical processes, in order to produce H2.

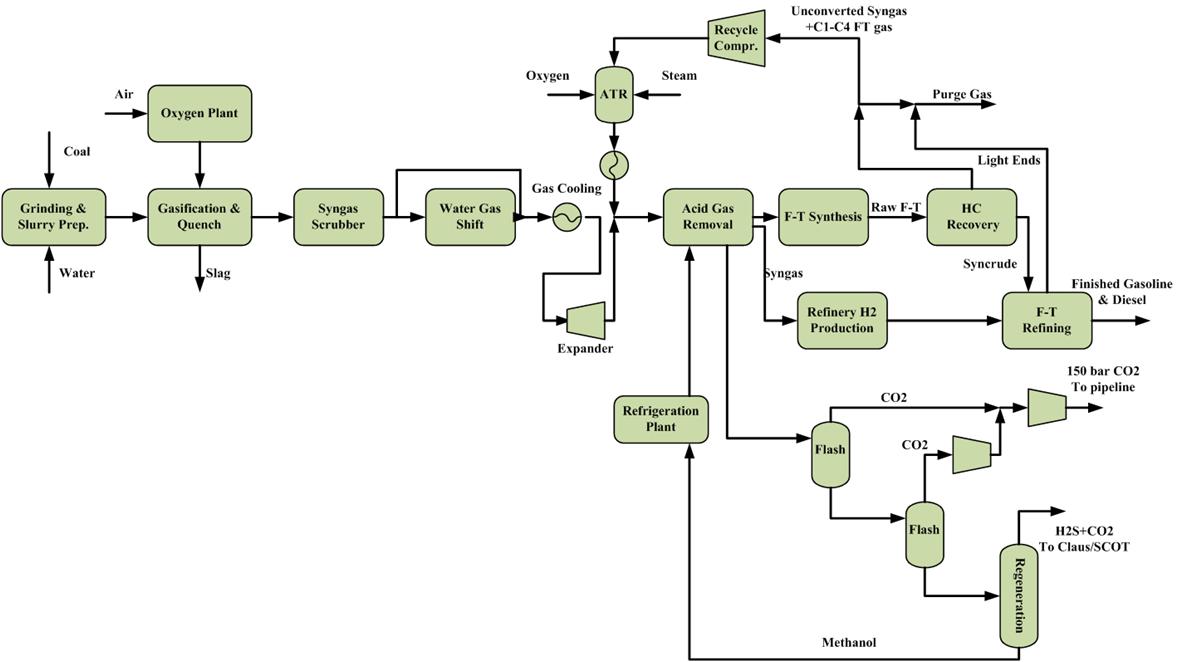

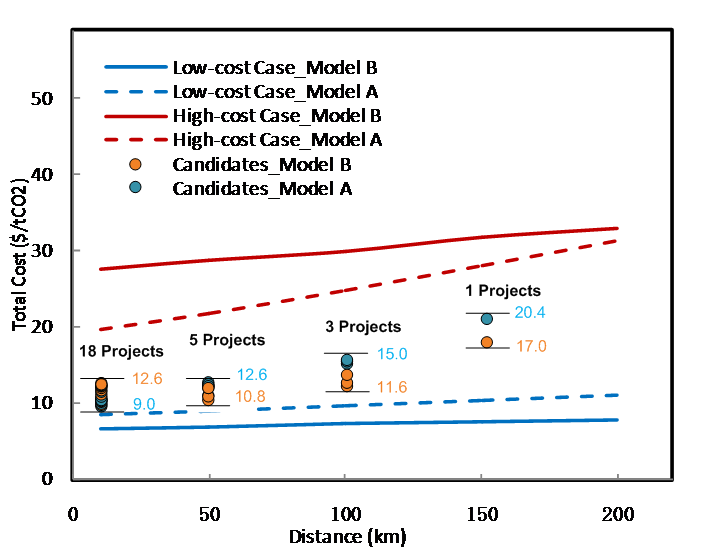

Figure 2: Schematic of typical coal to chemicals or synfuels plants; CO2 is generated during the water-gas shift reaction process. Then high purity CO2 can be captured for storage at the acid gas removal process, instead of emitting to the atmosphere directly. When I came back from the trip, we initiated another research project with Prof Zheng Li of Tsinghua University, Dr. Robert Williams and Dr Eric Larson from Princeton Environmental Institute. The focus is was to have a thorough evaluation of the clean coal processes , where high purity CO2 is was generated and emitted; also to carry out a complete scan within China on how many of these projects are were operating, under-construction and under planning, since China is unique in its ambition in clean coal technology considering its coal-based energy structure. We also compared the existing economic analysis methods and modified it to fit the case for China.  Figure 3: Preliminary cost estimates for the potential early saline aquifer storage CCS projects in China. The “Nth plant” cost estimates for the 18 projects where the CO2 source is within 10 km of a sink, are between 9 and 13 $/tCO2. The highest cost estimate among all evaluated projects was less than $21/tCO2. (figure from Ref.1) Concluding remarks: China is uniqueWe conclude here that China is unique in the large number of existing and planned coal chemical projects. Taking advantage of the relatively low cost of capturing these CO2 streams, as compared with capturing CO2 from power plant flue gases, some of the 20 large-scale CO2 capture and storage demonstration projects called for by the leaders from the G8, to be deployed during the next decade, might be expeditiously located in China. This suggests that there would be mutual value in international cooperation to support CCS demonstration projects in China, including international sharing of costs for such demonstrations. Also CO2 Enhance Oil Recovery (EOR) expertise in the U.S. and other countries might be transferred to help CO2 EOR implementation in China’s oil fields, and there is likely to be strong international interest in supporting monitoring, modeling, and CO2 storage verification activities for CO2 EOR projects, as well as for aquifer storage projects.

(Zhong Zheng would like to thank Nicolas Lefevre-Marton, Kang Sun, and Hang Deng for their useful comments and critical reviews on an early draft of this perspective article before CEG posts it. )

Main References: 1. Zhong Zheng, Eric D. Larson, Zheng Li, Guangjian Liu, Robert H. Williams. Near-Term Mega-Scale CCS Demonstration Opportunities in China. Energy and Environmental Science. Energy Environ. Sci., 2010, 3, 1153-1169. |

|

Copyright 2012 by Princeton University China Energy Group. All rights reserved. |